What is TMT Bar?

Thermo-Mechanically Treated bars have the softer core and harder outer surface. TMT Rebars manufactured through hot rolling of steel billets followed by Thermo Mechanical Treatment (Quenching & self-tempering) process.

Step 1

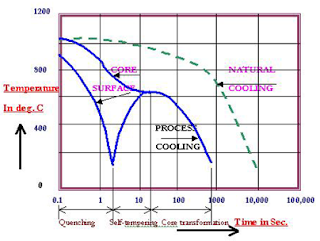

Quenching is the first stage for manufacturing TMT Bar. Hot rolled bar leaves the final mill stand and extinguished using water spray system in the quenching box. This process helps to harden the outer core while the inner core remains hot and soft.

Step 2

Self-tempering is the second stage where bar leaves the quenching box and the inner core continues to supply heat to the outer surface since it is relatively hot. This heat helps to create a structure to the outer base that is called Tempered Martensite.

Step 3

Atmospheric cooling is the third stage that takes place on cooling beds, where the austenitic core gets transformed into a ductile ferrite-pearlite structure. Thus the final structure consists of a stronger outer layer (Tempered Martensite) with a ductile core (Ferrite Pearlite)

Comments

Post a Comment